Starting Right

Doing It Right

Cedar Breather®

Cedar Breather® is the solution for preserving the beauty and life of wood roofing. As an underlayment for wood shingles and shakes, Cedar Breather provides space for a continuous air flow between the solid roof deck and the cedar shingles. Benjamin Obdyke's patented three-dimensional design allows the entire underside of the shingle to dry, eliminating excess moisture, preventing thermal cupping and warping, and reducing potential rotting. For quick and easy installation, Cedar Breather rolls out over standard 30 lb. felt, installs without any special tools, and eliminates the need for furring strips. Its fire-resistant nylon matrix remains unaffected by UV light, heat or cold, for long-lasting, durable performance.

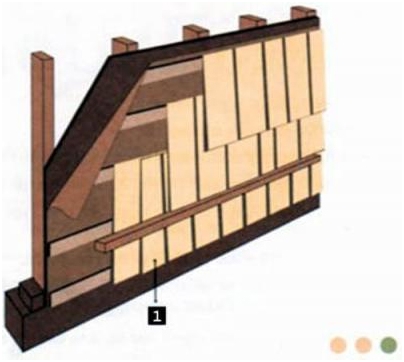

Shingling Existing Walls

Shingles are always nailed to 2.5 x 10 cm (1 x 4 in.) wooden laths fixed directly to the frame or existing wall covering.For courses, exposure and installation of shingles, follow steps for new construction walls.

Proper ventilation is essential:

Home Slicker effectively drains moisture from behind the siding, reducing the chances of premature peeling or blistering of finishes.Home Slicker’s unique three-dimensional Nylon matrix provides a continuous space for drying, channels for drainage, a thermal break, and pressure equalization, allowing moisture to escape quickly before it damages the sidewall materials. Wood, fiber cement and EIFS systems, as well as brick and vinyl, are ideal cladding systems for use with Home Slicker. With quick, easy installation, Home Slicker provides maintenance-free protection for the home.

Home Slicker™ is the answer for protecting wall systems from the damaging effects of moisture. Wind-driven rain from the outside, moisture vapor from the home’s interior, and corrosive surfactants that leak from certain types of siding, usually remain trapped in between the siding and building paper or housewrap. This unvented moisture can negatively impact the performance of siding systems and building paper or housewrap. It can also lead to the development of mold and mildew in the wall space, potentially creating health concerns. Unvented moisture behind cladding systems can also cause premature failure of paints or stains.

Materials: Only corrosion resistant nails or staples shall be used in applying Eastern White Cedar shingles, hip and ridge units and starters. Stainless steel (Type 304 or 316), aluminum, or hot-dipped zinc-coated steel nails and stainless steel staples have proven to give good service. Bright or blued steel and electro-galvanized nails and staples are not recommended.

Nails: Nails shall meet local building code requirements. Nails shall be long enough to penetrate through, or at least ¾” (19 mm) into the sheathing, battens, or furring, when driven flush with the surface of the shingle.

Note: The 1995 National Building Code of Canada (NBC 1995) specifies the use of nails having a minimum head diameter of 0.19” (4.8 mm) and a shank thickness of not less than 0.08” (2.0 mm).

Nailing Chart – Roofs

| Type | Gauge & Minimum Nail Length |

Number of Nails | |

| New Roof Shingles | 16" (400mm) shingles |

1 ¼" (32 mm) long No. 14-½ gauge |

2 only |

| Re-Roof Shingles | 16" (400mm) shingles |

1 ¾" (44mm) long box nails |

2 only |

Note: For thick material, nails should penetrate through, or at least ¾” (19 mm) into the sheathing.

Nailing Chart – Sidewalls

| Type | Gauge & Minimum Nail Length |

Minimum Number of Nails |

Maximum Nail Spacing |

| 16" (400mm) Shingles | 1 ¼" (32 mm) long No. 14-½ gauge |

2 | 3 nails in shingles over 8" (200mm) wide |

| Double-Course sidewall | 1¾" (44 mm) long casing nails |

2 | 4" (100mm) on center |

Note: For thick material, nails should penetrate through, or at least ¾” (19 mm) into the sheathing.

Staples :

Staples shall be minimum 16 gauge or of equivalent cross-sectional area with a crown width of 7/16” (11 mm). Staples shall be long enough to penetrate through, or at least ¾” (19 mm) into the sheathing, battens, or furring, when driven flush with the surface of the shingle. Staples shall be driven so that their crown is aligned parallel to the exposure line, i.e. across the grain of the shingle.